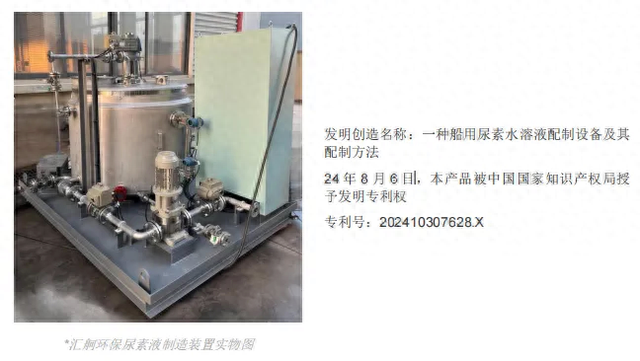

AG百家乐能赢吗 汇舸环保生效请托船用尿素液制造安装

2024 年底,汇舸环保自主研发制造的船用尿素液制造安装,顺利请托位于日本今治的浅川船坞。设置合座性能盘算推算达到国外跳动水平,坐蓐的尿素液居品,弥散满足 ISO 18611-1:2014 船用氮氧化物规复剂的质料特色,即浓度为 40%的尿素液(AUS 40)。

据统计 2008 年,环球海运船舶的耻辱物排放量占 NOx 和 SOx 排放总量的 18%-30%和 9%。因此,国外海事组织(IMO)推出了可谓史上最严苛的 IMO Tier III 排放尺度,其条款与 Tier II 尺度比较,2 / 4相宜 Tier III 尺度的发动机的氮氧化物排放量须减少近 76%。而刻下相宜 IMO NOx Tier III 排放尺度限值的现存本事包括:取舍性催化规复 SCR (Selective Catalytic Reduction)系统、废气再轮回安装 EGR(Exhaust Gas Recirculation)、替代燃料等。SCR 本事是裁汰 NOx 排放较为有用的阶梯之一, 可有用脱硝 70–90%以上。

SCR 本事是指在催化剂(庸碌使用催化剂是 V2O5/TiO2)的作用下,讹诈规复剂(如 NH3、液氨、尿素)来“有取舍性”地与烟气中的 NOx反映并生成无毒无耻辱的 N2 和 H2O。

因此聘请 SCR 本事的船舶必须补充和储存尿素液。然而,尿素液的采购本钱和运载本钱高于颗粒尿素,何况尿素液的储存时辰有限,制造商提议自坐蓐之日起有用期经常为 6 到 18 个月(与储存温度干系)。

AUS40 尿素液可采购的口岸有限,必须大王人购买储存,而未使用的残留尿素液则很可能过时,永恒储存后要是使用前要素测试效果隔离格,必须进行甩手接续,或在 III 级松手区域外强制破钞。另外,好多口岸不回收 IBC 尺度的尿素液包装容器,甩手本钱很高。

现在装船使用中的尿素液制造安装,AG百家乐下载盛大存在尿素颗粒溶化不透顶,加料不简单,制造时溢出的气体耻辱舱室环境等问题。

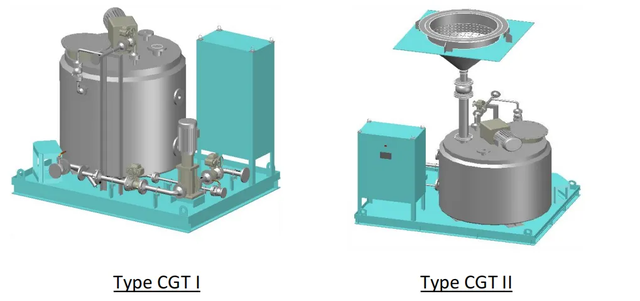

针对上述问题,通过采用聚拢各方的安装和操作提议,汇舸环保自主研发瞎想了 CGT 系列尿素液制造安装。用船舶造水机坐蓐的纯水按配比加入定量的尿素颗粒后,在搅动罐内充分搅动,同期对搅动罐夹套内的加热用淡水进行加热,加速和确保尿素颗粒透顶溶化。同期罐体增多排气口,按需引管到翻开船面,使得尿素液制造神情的环境可视为零耻辱,确保了尿素液 AUS4O 坐蓐的安全性和高质料。

现在,各种规格型号的尿素液制造安装在海表里阛阓,特地是日本、韩国,得回高度招供,并取得了邃密的销售事迹。

在船用 AUS40 尿素液制造安装基础上,汇舸环保也已生效研发了陆用 AUS32 尿素液制造安装,详尽了纯水制造和尿素液定量加注安装的神色,满足陆岸上重载卡车的尿素液需求,以城市用水输入,AUS40/AUS32 输出的时势,满足阛阓需求。

Name of invention:

A type of marine urea solution preparation equipment and its preparation method.

The product was authorized the invention patent by the State Intellectual Property Office of the People’s Republic of China on 6th Aug, 24.

Patent number: 202410307628.X

At the end of 24, Marine Urea solution production plant were successfully delivered to Asakawa Shipyard in Imabari, Japan. it was independently developed and manufactured by ContiOcean . The performance of the equipment has reached the international leading level, and the production of urea solution meet the quality characteristics of ISO 18611-1:2014--Marine NOX reduction agent AUS40- aqueous urea solution at 40 % concentration (AUS 40).

According to statistics, in 2008, the pollutant emissions of global maritime vessels accounted for 18%-30% and 9% of the total NOx and SOx emissions. As a result, the International Maritime Organization (IMO) has introduced the most stringent IMO Tier III emissions standards in history, requiring a nearly 76% reduction in NOx emissions from Tier III-compliant engines compared to Tier II standards. Existing technologies that meet IMO NOx Tier III emission limits include: Selective Catalytic Reduction (SCR) system, Exhaust Gas Recirculation (EGR), alternative fuels, etc. SCR technology is one of the more effective methods to reduce NOx emissions, It can effectively remove more than 70-90% of the nitrate.

SCR technology refers to the use of reducing agents (such as NH3, liquid ammonia, urea) to "selectively" react with NOx in flue gas and generate non-toxic and pollution-free N2 and H2O under the action of a catalyst (widely used catalyst is V2O5/TiO2).

Therefore, ships adopt SCR technology must replenish and storage urea solution. But the procurement cost and transportation cost of urea solution are higher than that of urea granules, and the storage time of urea solution is limited, and the manufacturer recommends an expiration date from the date of production: Usually 6 to 18 months (depending on storage temperature).

AUS40 urea solution can be purchased from a limited number of ports, so must be purchased in bulk for storage, but unused residual urea solution is likely to expire, and If the composition test results fail before use after long-term storage, it must be disposed of or forced consumption outside a Level III restricted area. In addition, many ports do not recycle IBC standard urea solution packaging containers, and the cost of abandonment is high.

At present, the urea solution production plant used on ships generally has problems, such as incomplete dissolution of urea granules, feeding trouble, and engine room environmental pollution of by gas overflow during manufacturing.

In view of the above problems, ContiOcean independently developed and designed the CGT series urea solution production plant, by adopting the installation and operation suggestions of various parties. Quantitative urea granules are added to the pure water produced by the ship's water generator according to the ratio, and are fully stirred in the mixing tank, while jacketed heating is used to speed up and ensure the complete dissolution of urea granules. At the same time, an exhaust port is added to the tank, and the pipe is led to the open deck as needed, so that the environment of the urea solution production plant site can be regarded as zero pollution. Ensure the safety and high quality of AUS4O production of urea solution.

At present, urea solution production plant of various specifications and models have been highly recognized in domestic and overseas markets, especially in Japan and South Korea, and have achieved good sales performance.

On the basis of the Marine AUS40 urea solution production plant, Contiocean has also successfully developed AUS32 for vehicles, which integrates the form of pure water generator and urea solution quantitative filling deviceAG百家乐能赢吗, the urban water input, AUS40/AUS32 output mode, to meet the market demand.